Laboratory Pelletising Systems

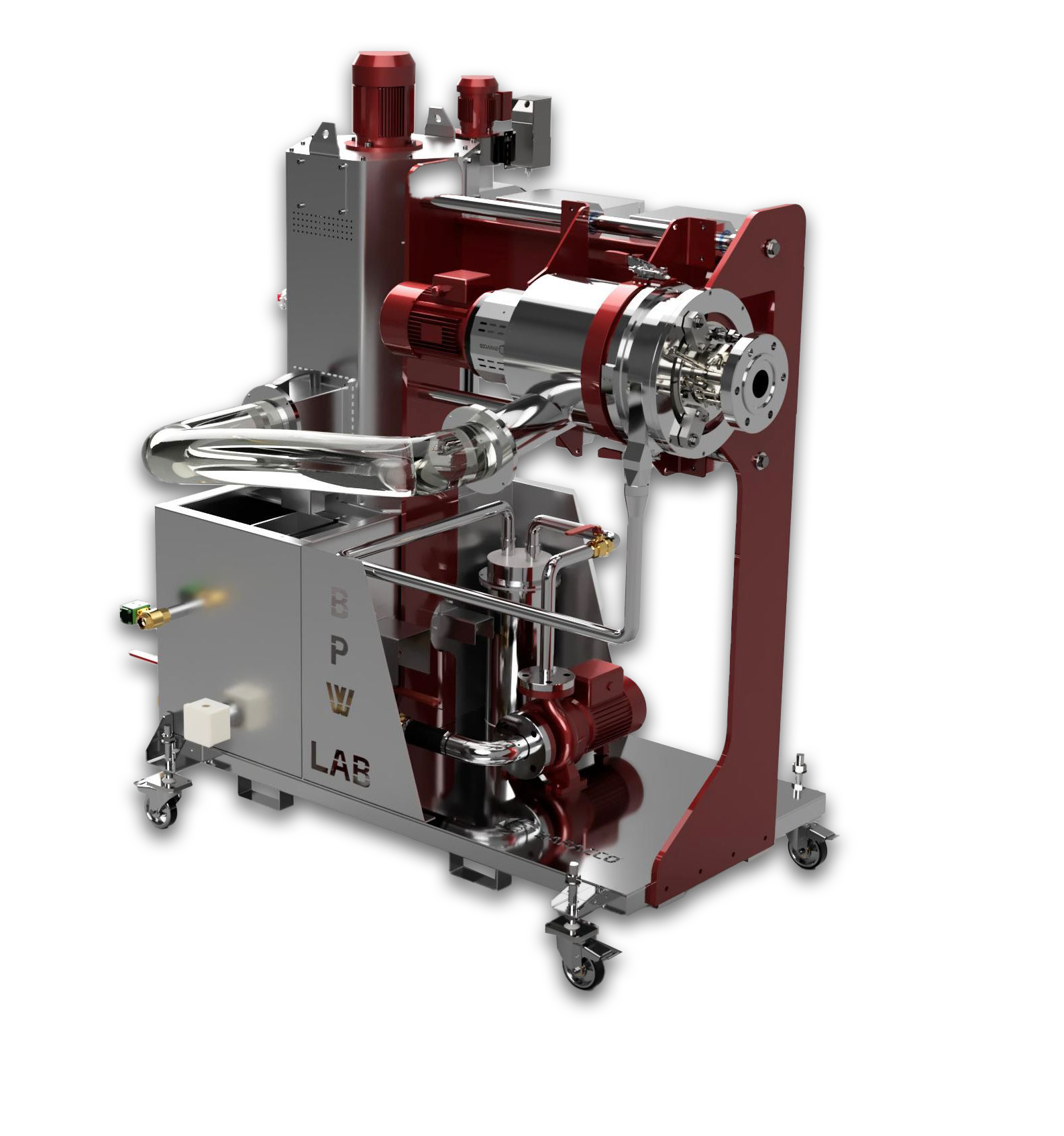

BPW

Baracco laboratory pelletising systems

BPW50

The laboratory pelletising system is specifically designed for laboratory development work , to produce samples or small batches of pellets from lightweight materials such as polyolefins and others.

The system is designed to have a production capacity of up to 100 kg/h (20 – 220 lbs/h), depending on the material.

How Baracco pelletising systems work

This pelletising system, including centrifugal dryer, is mounted on a single, easily movable frame with swivel wheels and incorporates unique features for both laboratory use and small continuous production runs.

All necessary electrical controls, based on state-of-the-art touch screen technology, are contained in a modular panel that rests on the system frame.

All necessary electrical controls, based on state-of-the-art touch screen technology, are contained in a modular panel that rests on the system frame.

Benefits of our BPW systems

Easy to clean

Simple and easy to use

Lightweight, portable

Designed to be convenient

Requires few inexpensive spare parts

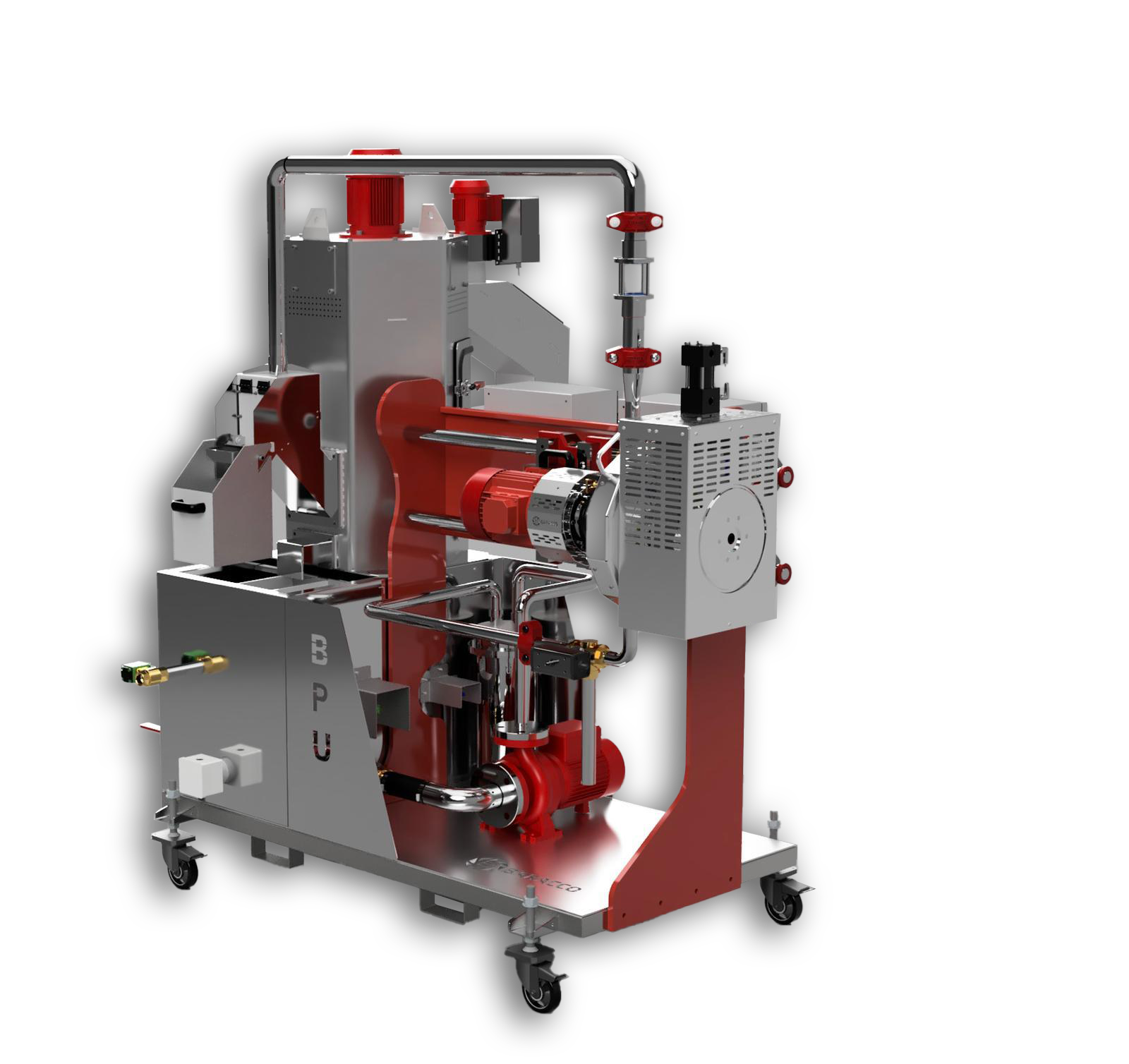

BPU

Baracco Laboratory Pelletising Systems BPU2

Our BPU2 is a compact, easily transportable system capable of producing small batches.

It has the same structure and operation as a standard Underwater system, but its small size makes it ideal for laboratory testing and material research, or for companies that need to achieve small output capacities.

It has the same structure and operation as a standard Underwater system, but its small size makes it ideal for laboratory testing and material research, or for companies that need to achieve small output capacities.

It has a production capacity of approximately 100 kg/h and can be customised to customer specifications.

How Baracco pelletising systems work

This pelletising system, including centrifugal dryer, is mounted on a single, easily movable frame with swivel wheels and incorporates unique features for both laboratory use and small continuous production runs.

All necessary electrical controls, based on state-of-the-art touch screen technology, are contained in a modular panel that rests on the system frame.

All necessary electrical controls, based on state-of-the-art touch screen technology, are contained in a modular panel that rests on the system frame.